a disruptive technology...

Our technology aims to develop the drawing of single crystals towards a process industrial in magnetic cold crucible, more energy efficient without the use of polluting crucibles. This same technology allows the development of premium crystals, perfect for many applications such as lasers, semiconductors, scintillators, micro-electronics...

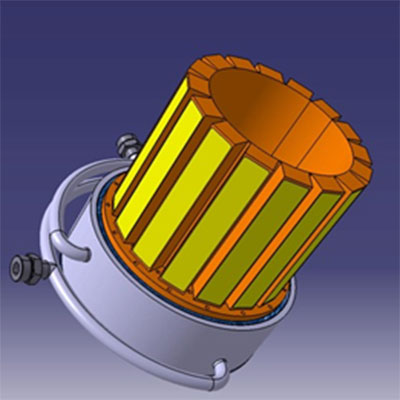

cold crucible principle

The innovative nature of the technology lies in the use of a new cold magnetic crucible. There is no innovation in hot crucible technology. It is clear that cold crucible technology will replace hot crucible technology for undeniable reasons of quality of the materials produced, energy consumption of the processes and economic profitability.

The innovative nature of the technology lies in the use of a new cold magnetic crucible. There is no innovation in hot crucible technology. It is clear that cold crucible technology will replace hot crucible technology for undeniable reasons of quality of the materials produced, energy consumption of the processes and economic profitability.

Today, the cold crucible is a widely used process for producing polycrystalline metallic materials (Titanium, Nobium etc...) at high temperatures (up to over 2000°C) without external pollution, unlike graphite or alumina crucibles. It was invented by Siemens in 1926 for metallurgical applications.

The scientific and technological challenges stem from the use of the cold crucible to grow single crystals from a liquid bath. A key point concerns the adjustment of the electromagnetic system to make it compatible with the pulling of single crystals: temperature gradients, agitation and the shape of the interface must be controlled while ensuring growth stability.

many advantages

The technology of pulling single crystals in a cold magnetic crucible enables :

- The development of crystals with higher purity and more homogeneous doping levels

- Saving energy and time during the printing process

- The development of crystals that are currently inaccessible using conventional methods

- Reduce the cost of crystals (as opposed to the noble materials used today)

- Longer service life for manufacturing equipment due to the nature of the process, based on the principle of induction with cooled copper sectors.

The process is very important in the energy transition because it significantly reduces the production of CO2 (variable depending on the crystals).