The Cold Crucible : Operation and Advantages

Issue of December 3, 2024

In the world of materials science, understanding the cold crucible principle is essential. This knowledge benefits researchers, engineers and technicians in crystal growth. Detailed information on how it works, the materials used and its effectiveness can inform their daily work, optimize their production methods and improve yields.

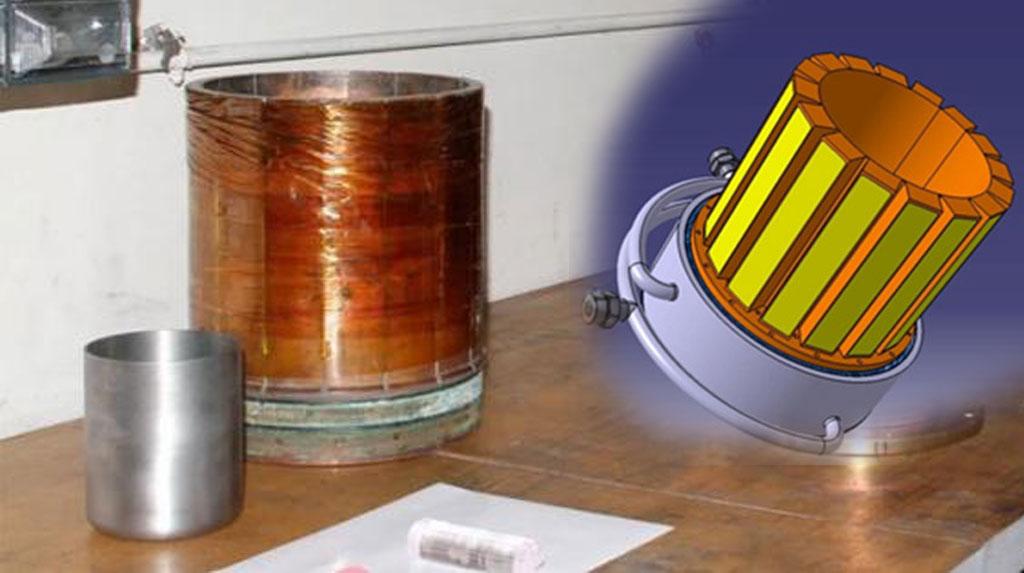

The elements of the cold crucible

The main container

The central element of the cold crucible is the main container. It is a large compartment, designed to withstand extremely low temperatures. Its endurance and structure allow prolonged use without significant changes in its physical properties. The component used for the construction of the receptacle must necessarily be an excellent thermal conductor in order to ensure optimal and uniform heat dissipation of the elements deposited there.

Thermal insulation

Another vital component of the cold crucible is the thermal insulator. It prevents the influence of external heat on the internal conditions of the main container. The thermal insulator may differ in nature, depending on the specific requirements of each use, but it must always show an exceptional insulation performance with low conductivity, even at very low temperatures.

It serves as a protective shield around the contents of the cold crucible, thus preserving the integrity of the low temperature elements against any unwanted external disturbance.

Thanks to the harmonious combination of these two key elements – the main container and the thermal insulator – the cold crucible provides a stable environment suitable for scientific experiments carried out under controlled cryogenic conditions.

General operation

The principle of the cold crucible is based on an innovative and complex technical process. This technology is widely used for melting substances at high temperatures under specific conditions, where heat production cannot be done by conventional methods.

Its operation is based on the exploitation of quantum and thermodynamic phenomena, in particular the tunnel effect which allows low-energy particles to cross a considerable energy barrier. The crucible maintains a relatively low temperature while the material it contains reaches extreme levels of heat.

To put it simply, when an electrical voltage is applied to the cold crucible, the ions are propelled towards the target material where they collide with the atoms of the material, thus causing a thermonuclear reaction without the need for an external heat source.

It is this exceptional feature that gives the cold crucible its name and highlights its ability to radically disrupt industrial processes requiring high-temperature operations while reducing the environmental impact linked to traditional heat production.

Materials used

The efficiency of the cold crucible depends largely on the choice of materials used. Firstly, stainless steel is preferred for its robustness and its immunity to corrosion, guaranteeing a prolonged service life of the equipment.

In addition, ceramic is frequently used for its thermal insulation qualities. It helps maintain a constant temperature within the crucible while minimizing energy losses.

Some models incorporate graphite elements for their exceptional conductive properties which optimize the overall efficiency of the system.

These three materials complement each other and cooperate harmoniously to ensure optimal operation of the cold crucible. Their careful selection illustrates the technical precision required in the design of this type of sophisticated device.

The application in crystal growth

The growth of single crystals

The application of the cold crucible in the field of crystal growth is particularly remarkable. Its ability to establish stable and controlled conditions facilitates the creation of single crystals, the cornerstone of high-tech industries. The precise control of the process avoids structural anomalies, ensuring optimum quality for these singular crystals.

Crystal Drawing

Pulling is one of the crucial phases of the crystal growth process via the cold crucible. It is necessary to extract the crystal carefully in order to maintain its intact structure and preserve its intrinsic properties. A slow and steady movement is essential during pulling to prevent any distortion or cracking that could compromise the integrity of the crystal.

Control and improvement

Last but not least, strict control and refinement are essential to ensure that each single crystal reaches its maximum potential. This requires a detailed assessment of every aspect, from atomic alignment to chemical purity to exact physical dimensions. Any irregularities detected must be rectified before the crystals are used in their final applications.

Effectiveness and benefits

Higher energy efficiency

The cold crucible, thanks to its innovative design, offers unprecedented energy efficiency. This technology results in a significant reduction in energy consumption compared to traditional crystal growth techniques. The secret lies in the thermal insulation of the crucible which reduces energy losses, thus increasing the overall efficiency of the process. This notable progress in energy efficiency generates significant savings for companies and promotes more environmentally friendly production.

Significant qualitative benefits

Far from being only energy efficient, the cold crucible also has notable qualitative advantages. It produces very pure and uniform crystals thanks to precise control of thermal conditions during growth. Thus, it ensures not only better quality control of the final product but also better reproducibility between different batches produced. These characteristics are particularly attractive in industries requiring high-performance crystalline materials such as semiconductors or photovoltaics where every detail counts to optimize the final performance of the product.